JN White is an ISO 9001:2015 and ITAR-certified manufacturer of labeling machinery, graphic overlays, and custom labels. We handle projects of a variety of sizes, and we have the expertise to translate what our customers need into high-quality, high-precision outcomes.

U.S. Tape & Label specializes in providing quality labeling equipment, automatic labeling, bar code labeling, labeling applicators, labeling systems and customized labelers. We offer the finest labeling machinery on the market today with a multitude of functions to fulfill all your labeling needs.

At Matthews Marking, we pride ourselves on providing advanced labeling machinery that meets the diverse needs of our clients across various industries. Our cutting-edge technology ensures precision and reliability in every application, from high-speed production lines to specialized marking tasks. We understand the critical importance of accuracy and consistency in labeling, our solutions are...

Since 1989, Label Mill has focused on label applicators and printer applicators. Label Mill has designed and built a full line of labeling solutions that have set new standards for simplicity of design, reliability, and ease of use. We have earned a reputation for developing custom solutions to meet the ever growing unique requirements for each individual customer and application.

Total solutions are our company goal. No matter whether you need flexible packaging, pressure-sensitive labels, or automatic labeling equipment, we have it all. We also offer customized service and support to all customers. We believe in offering the latest technology and service to all customers, and we even offer RFID services. You can learn more when you contact us today!

More Labeler Manufacturers

A labeler might include a complete labeling system or individual parts such as a printer, dispenser or applicator.

Cosmetics, pharmaceutical, medical, automotive, aerospace, electronics, food and beverage, waste treatment, agriculture and shipping industries are just a few that utilize labels in everyday operations. To accommodate these needs, several product configurations are available. Hand held devices are used in low production or personal applications such as office organization whereas bench or table top models are larger and often provide more adjustability for retail and commercial purposes.

Industrial label machines are heavy-duty and floor mounted systems that can provide continuous or batch labels that are applied accurately even with high production rates. Labeling machines of any size can provide vertical or horizontal wrap around labels as well as front, top, back or bottom application of labels.

Labelers allow for customized or mass production of these identification tags, which may serve as just that or provide other information such as content, nutritional value, care instruction, warnings, shipping and handling, barcodes, prices, logos or even simply décor.

All labeling processes begin with an analysis of the application. Once the size, materials and dimensions are determined, the information can be transferred to a label printer. While common household printers may be used, specialized printers are widely available and capable of printing on much more than paper.

Metals, glass, fibers, plastic and virtually all other materials can be dyed, engraved or embossed as needed to create a label. Rigid labels are printed onto metals or plastics while flexible labels are printed on paper that may or may not have adhesive backing. Label dispensers are then used to expel the materials from the printer and remove this backing or otherwise ready the signage for application.

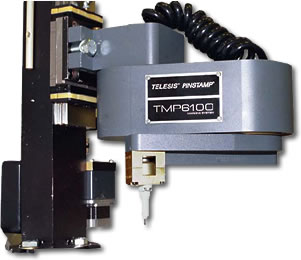

Label applicators then use one of three methods to apply the labels. Touch or tamping physically taps the pressure sensitive materials onto the product. Air blowing uses a powerful surge of air while wipe labels are wrapped on. While manual application is permissible in many applications, it does not offer the speed and accuracy of automated systems.

Before printing, dispensing, applying or even designing, it is important to consider the size and material construct of the label needed as machine capabilities will vary significantly. The composition of the substrate to which the tag will be applied is also important as it must be compatible with the adhesive glue or other fastening device used.

Glass, plastics, metals, foils, papers, bottles and other containers list just a few of the possible surfaces to which labels are commonly applied. While branding is most often a choice, several other labels are required by national or international regulatory committees in order to ensure safe practices and full disclosure.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services