JN White is an ISO 9001:2015 and ITAR-certified manufacturer of labeling machinery, graphic overlays, and custom labels. We handle projects of a variety of sizes, and we have the expertise to translate what our customers need into high-quality, high-precision outcomes.

U.S. Tape & Label specializes in providing quality labeling equipment, automatic labeling, bar code labeling, labeling applicators, labeling systems and customized labelers. We offer the finest labeling machinery on the market today with a multitude of functions to fulfill all your labeling needs.

At Matthews Marking, we pride ourselves on providing advanced labeling machinery that meets the diverse needs of our clients across various industries. Our cutting-edge technology ensures precision and reliability in every application, from high-speed production lines to specialized marking tasks. We understand the critical importance of accuracy and consistency in labeling, our solutions are...

Since 1989, Label Mill has focused on label applicators and printer applicators. Label Mill has designed and built a full line of labeling solutions that have set new standards for simplicity of design, reliability, and ease of use. We have earned a reputation for developing custom solutions to meet the ever growing unique requirements for each individual customer and application.

Total solutions are our company goal. No matter whether you need flexible packaging, pressure-sensitive labels, or automatic labeling equipment, we have it all. We also offer customized service and support to all customers. We believe in offering the latest technology and service to all customers, and we even offer RFID services. You can learn more when you contact us today!

More Label Machine Manufacturers

Some specialized label machines also exist. These include rotary labeling systems for bottles and special printers and applicators for RFID and security tags.

Labels are instructional or descriptive tags attached to many products and packages on the market today. They are also used to communicate the price of an object, as well as functioning as easy to read package delivery directions. With so many uses, labeling is rarely done manually.

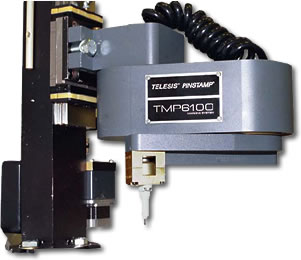

There are a variety of labeling machines that produce and attach labels to products that require them. Printers and applicators are the most well known in the label machine industry. Label printers are generally high-quality, fast-working thermal transfer printers. Specialized label printers, which can have the label information inputted and then printed immediately, exist for a variety of applications such as in laboratories and for hospital wristbands.

Printer applicators both print and apply labels for nearly any packaged good. These systems are often used in a context that requires more individually designed labels then multiple labels that are all the same. Labels may identify the product and brand specifically or they may have added information such as nutritional facts, product warnings or bar codes.

Label applicators apply labels to individual products. They come in air-blow and tamp-blow varieties that blow labels onto products quickly and accurately. The tamp blow variety is sometimes designed to apply two labels onto two products at once, a popular style of label applicator because of its efficiency.

Another type of label applicator is the wipe-on applicator, which wipes labels onto products, including around corners and on curved and unusually shaped products. For more complicated labeling needs, labeling systems can be used. Labeling systems are integrated systems that include label printing and applying, integrated conveyor belts, and computerized controls. They perform automatically, and are units with a high level of productivity.

Such systems are found in industrial manufacturing or food processing and packaging plants, where mass amounts of products are being barcoded and detailed daily. Adhesive is always used to apply the labels, although the type of adhesive varies. Pressure sensitive and heat shrink are the most common styles; heat shrink is employed by most labeling systems, while pressure sensitive adhesives are common in individual label applicators.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services